Home > Cases > Case Study: Efficient Pipeline Inspection with Portable HD pipe camera V9

Case Study: Efficient Pipeline Inspection with Portable HD pipe camera V9

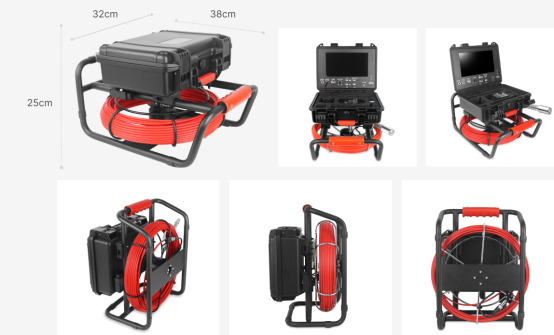

9inch Portable Pipe Inspection

Challenge

Pipe Diameter Constraints: Existing equipment struggled to navigate narrow 110mm pipes.

Image Clarity: Low-resolution cameras failed to detect fine cracks or blockages.

Cable Durability: Frequent snags and breaks in rigid cables caused inspection interruptions.

On-Site Visibility: Field technicians needed real-time, high-definition visuals for immediate decision-making.

Solution: Vicam HD Portable Pipeline Inspection Camera V9-23

The client adopted “Vicam Portable pipe camera”, featuring:

1. 23mm 1080P Full HD Self-Balancing Camera:

– Compact design ideal for 110mm pipelines.

– Auto-adjusts lighting and image stability in dark, uneven environments.

2. 9-inch HD Display:

– Provides real-time, crystal-clear visuals for on-site analysis.

3. 30m Fiberglass-Reinforced Cable (5.2mm Diameter):

– Exceptional flexibility and tensile strength to navigate bends and obstacles.

– Waterproof and corrosion-resistant for harsh pipeline environments.

Implementation

Technicians deployed the system to inspect a 110mm drainage pipeline suspected of blockage. The camera’s slim profile allowed smooth entry, while the fiberglass cable enabled traversal of multiple 90-degree bends. The self-balancing camera automatically corrected its orientation, delivering stable footage even in turbulent water flow. The 9-inch display enabled the team to identify a partial blockage caused by tree roots and minor joint misalignment, issues previously missed by older equipment.

Client Feedback

“The pipe endoscope revolutionized our workflow. The image quality is unmatched, and the cable’s toughness is a game-changer. We’ve cut downtime by 60% and improved repair targeting.”